Polishing Supports

Model

- Product Description

- Product Specification

TOUCHLAM® polishing cloths & pads

LAM PLAN proposes a range of exclusive TOUCHLAM® polishing cloths and pads.

LAM PLAN proposes a range of exclusive TOUCHLAM® polishing cloths and pads.

We conceive and produce all our TOUCHLAM® products, favoring quality results through the selection of materials and treatments.

Quality of results

The structure and the composition of a polishing support have a direct impact on the properties of the associated free abrasive during a polishing process. LAM PLAN has designed a range of polishing cloths & pads according to their capacity to optimize the abrasive functions in order to obtain an optimum quality of results.

The structure and the composition of a polishing support have a direct impact on the properties of the associated free abrasive during a polishing process. LAM PLAN has designed a range of polishing cloths & pads according to their capacity to optimize the abrasive functions in order to obtain an optimum quality of results.

LAM PLAN guides you in your clothes and pad selection according to your results expectations

| Application | TOUCHLAM® cloths |

Characteristics | |||

|---|---|---|---|---|---|

| SR* | Flatness | Finishing | Super Finishing | ||

| Fine grinding of soft materials Polishing of hard or extra hard material | 2FC1 | ✔ | ✔ | ||

| Rough polishing on ductile material | 2TT1 | ✔ | ✔ | ||

| Rough polishing on ductile material | 2TT2 | ✔ | ✔ | ||

| Fine polishing (intermediary)on all materials Final polishing on hard materials |

2TS3 | ✔ | ✔ | ||

| Fine polishing (intermediary) on all materials | 2TS4 | ✔ | ✔ | ||

| Fine polishing (intermediary) on soft materials | 3SE2 | ✔ | ✔ | ||

| Fine polishing (intermediary) on soft materials | 3SA4 | ✔ | ✔ | ||

| Medium to fine polishing on semi-hard to hard (uncoated) |

3TL1 | ✔ | |||

| Final polishing on semi-hard materials |

3FV1 | ✔ | |||

| Final polishing on soft to semi-hard materials |

4FV3 | ✔ | |||

| Final polishing (chemical/mechanical) on varied materials | 4MP1 | ✔ | |||

| Final polishing (chemical/mechanical) on varied materials | 4MP2 | ✔ | |||

*Stoke Removal

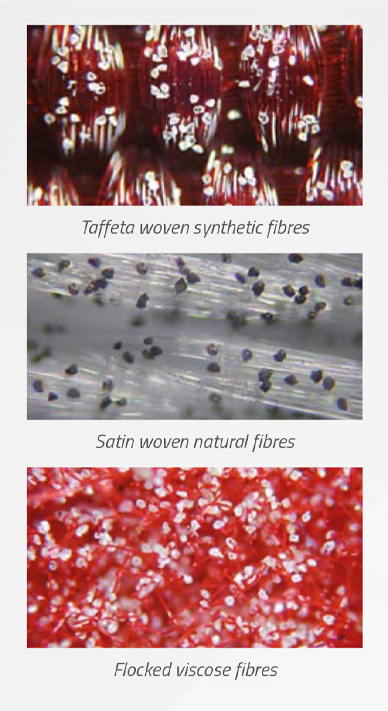

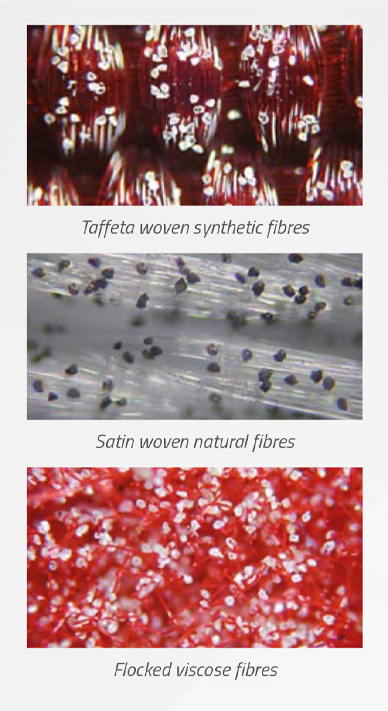

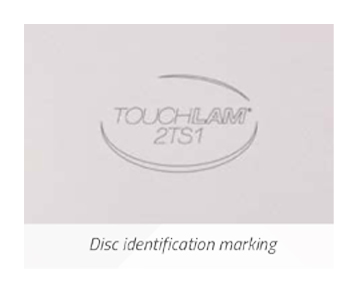

An example of a diamond abrasive,

spread over the different disc

structures

spread over the different disc

structures

Simplified use

The TOUCHLAM® cloths & pads are available in all standard diameters in two fixation modes: self-adhesive and magnetic.

The marking allows easy identification. A tab is now integrated into the discs to facilitate the removal of the protective foil of self-adhesive cloths.

See all our fastening systems pages FIXING ACCESSORIES.

The TOUCHLAM® cloths & pads are available in all standard diameters in two fixation modes: self-adhesive and magnetic.

The marking allows easy identification. A tab is now integrated into the discs to facilitate the removal of the protective foil of self-adhesive cloths.

See all our fastening systems pages FIXING ACCESSORIES.

| Mode | Description | Self-adhesive | Magnetic | X-LAM | ||

|---|---|---|---|---|---|---|

| Ø in mm | Ref. | Qty. | Ref. | Ref. | ||

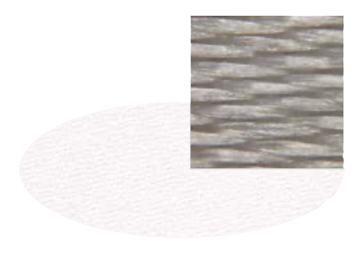

TOUCHLAM® 2FC1 |

Impregnated non-woven fibres. Stoke removal, finishing on extra hard materials. Usabl with diamond abrasives from 3 to 9 μm. |

200 | 5 units | 2FC10A02005 | 2FC10M02005 | 2FC10X02005 |

| 230 | 5 units | 2FC10A02305 | 2FC10M02305 | 2FC10X02305 | ||

| 250 | 5 units | 2FC10A02505 | 2FC10M02505 | 2FC10X02505 | ||

| 300 | 5 units | 2FC10A03005 | 2FC10M03005 | 2FC10X03005 | ||

| 400 | 5 units | 2FC10A04005 | ||||

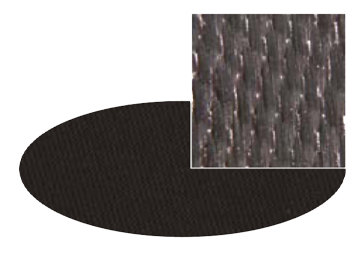

TOUCHLAM® 2TT1 |

Taffeta woven synthetic fibres. Stock removal and inherent flatness on difficult materials. Usable with diamond abrasives from 6 to 15 μm. |

200 | 5 units | 2TT10A02005 | 2TT10M02005 | 2TT10X02005 |

| 230 | 5 units | 2TT10A02305 | 2TT10M02305 | 2TT10X02305 | ||

| 250 | 5 units | 2TT10A02505 | 2TT10M02505 | 2TT10X02505 | ||

| 300 | 5 units | 2TT10A03005 | 2TT10M03005 | 2TT10X03005 | ||

| 400 | 5 units | 2TT10A04005 | ||||

TOUCHLAM® 2TT2 |

Taffeta woven synthetic fibres. Stock removal and inherent flatness on difficult materials. High durability. Usable with diamond abrasives from 6 to 15 μm. |

200 | 5 units | 2TT20A02005 | 2TT20M02005 | 2TT20X02005 |

| 230 | 5 units | 2TT20A02305 | 2TT20M02305 | 2TT20X02305 | ||

| 250 | 5 units | 2TT20A02505 | 2TT20M02505 | 2TT20X02505 | ||

| 300 | 5 units | 2TT20A03005 | 2TT20M03005 | 2TT20X03005 | ||

| 400 | 5 units | 2TT20A04005 | ||||

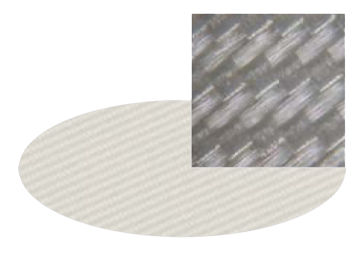

TOUCHLAM® 2TS3 |

Extra-thin satin woven natural fibres. Excellent inherent flatness and finishing, preservation of inclusions and edges, on all materials. Usable with diamond abrasives from 2 to 9 μm. |

200 | 5 units | 2TS30A02005 | 2TS30M02005 | 2TS30X02005 |

| 230 | 5 units | 2TS30A02305 | 2TS30M02305 | 2TS30X02305 | ||

| 250 | 5 units | 2TS30A02505 | 2TS30M02505 | 2TS30X02505 | ||

| 300 | 5 units | 2TS30A03005 | 2TS30M03005 | 2TS30X03005 | ||

| 400 | 5 units | 2TS30A04005 | ||||

TOUCHLAM® 2TS4 |

Satin woven natural fibres. Excellent finishing and flatness, preservation of edges, especially on samples composed of materials of various hardness or with coating. High durability. Usable with diamond abrasives from 1 to 6 μm. |

200 | 5 units | 2TS40A02005 | 2TS40M02005 | 2TS40X02005 |

| 230 | 5 units | 2TS40A02305 | 2TS40M02305 | 2TS40X02305 | ||

| 250 | 5 units | 2TS40A02505 | 2TS40M02505 | 2TS40X02505 | ||

| 300 | 5 units | 2TS40A03005 | 2TS40M03005 | 2TS40X03005 | ||

| 400 | 5 units | 2TS40A04005 | ||||

TOUCHLAM® 3SE2 |

Woven synthetic silk fibres. Finishing and flatness on soft materials. Usable with diamond abrasives from 1 to 3 μm. |

200 | 5 units | 3SE20A02005 | 3SE20M02005 | 3SE20X02005 |

| 230 | 5 units | 3SE20A02305 | 3SE20M02305 | 3SE20X02305 | ||

| 250 | 5 units | 3SE20A02505 | 3SE20M02505 | 3SE20X02505 | ||

| 300 | 5 units | 3SE20A03005 | 3SE20M03005 | 3SE20X03005 | ||

| 400 | 5 units | 3SE20A04005 | ||||

TOUCHLAM® 3SA4 |

Soft composite synthetic fibres Finishing on soft materials. Usable with diamond abrasives from 0,25 to 3 μm. |

200 | 5 units | 3SA40A02005 | 3SA40M02005 | 3SA40X02005 |

| 230 | 5 units | 3SA40A02305 | 3SA40M02305 | 3SA40X02305 | ||

| 250 | 5 units | 3SA40A02505 | 3SA40M02505 | 3SA40X02505 | ||

| 300 | 5 units | 3SA40A03005 | 3SA40M03005 | 3SA40X03005 | ||

| 400 | 5 units | 3SA40A04005 | ||||

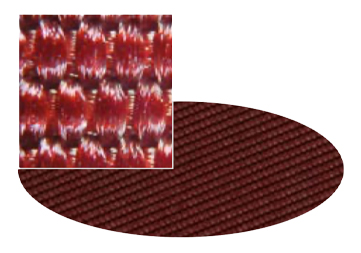

TOUCHLAM® 3TL1 |

High-resistant woven wool fibres. Adapted for the finishing of non-mounted samples High durability. Usable with diamond abrasives from 3 to 6 μm. |

200 | 5 units | 3TL10A02005 | 3TL10M02005 | 3TL10X02005 |

| 230 | 5 units | 3TL10A02305 | 3TL10M02305 | 3TL10X02305 | ||

| 250 | 5 units | 3TL10A02505 | 3TL10M02505 | 3TL10X02505 | ||

| 300 | 5 units | 3TL10A03005 | 3TL10M03005 | 3TL10X03005 | ||

| 400 | 5 units | 3TL10A04005 | ||||

TOUCHLAM® 3FV1 |

Semi-hard flocked short viscose fibres. Superfinishing, preservation of the inherent flatness on mounted hard materials. Usable with diamond abrasives from 1 to 3 μm. |

200 | 5 units | 3FV10A02005 | 3FV10M02005 | 3FV10X02005 |

| 230 | 5 units | 3FV10A02305 | 3FV10M02305 | 3FV10X02305 | ||

| 250 | 5 units | 3FV10A02505 | 3FV10M02505 | 3FV10X02505 | ||

| 300 | 5 units | 3FV10A03005 | 3FV10M03005 | 3FV10X03005 | ||

| 400 | 5 units | 3FV10A04005 | ||||

TOUCHLAM® 4FV3 |

Soft flocked long viscose fibres. Superfinishing on a large variety of materials, including very soft materials. Principally used with diamond abrasives from 0,25 to 3 μm but also with alumina suspension and colloidal silica. |

200 | 5 units | 4FV30A02005 | 4FV30M02005 | 4FV30X02005 |

| 230 | 5 units | 4FV30A02305 | 4FV30M02305 | 4FV30X02305 | ||

| 250 | 5 units | 4FV30A02505 | 4FV30M02505 | 4FV30X02505 | ||

| 300 | 5 units | 4FV30A03005 | 4FV30M03005 | 4FV30X03005 | ||

| 400 | 5 units | 4FV30A04005 | ||||

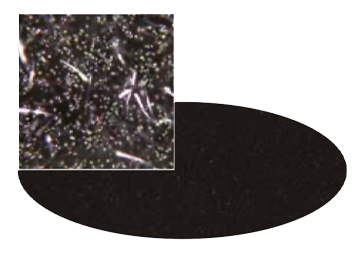

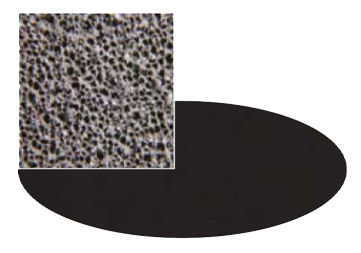

TOUCHLAM® 4MP1 |

Microporous polyurethane foam. Adapted to sensitive samples requiring an extreme super finish with chemical abrasives. Usable with oxides or colloidal silica. |

200 | 5 units | 4MP10A02005 | 4MP10M02005 | 4MP10X02005 |

| 230 | 5 units | 4MP10A02305 | 4MP10M02305 | 4MP10X02305 | ||

| 250 | 5 units | 4MP10A02505 | 4MP10M02505 | 4MP10X02505 | ||

| 300 | 5 units | 4MP10A03005 | 4MP10M03005 | 4MP10X03005 | ||

| 400 | 5 units | 4MP10A04005 | ||||

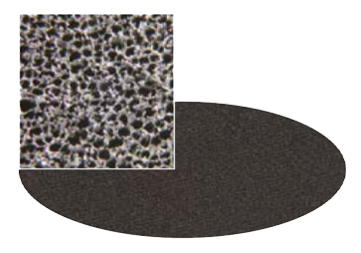

TOUCHLAM® 4MP2 |

Microporous polyurethane foam. High thickness. High durability, usable in the production process. Usable with oxides or colloidal silica. |

200 | 5 units | 4MP20A02005 | 4MP20M02005 | 4MP20X02005 |

| 230 | 5 units | 4MP20A02305 | 4MP20M02305 | 4MP20X02305 | ||

| 250 | 5 units | 4MP20A02505 | 4MP20M02505 | 4MP20X02505 | ||

| 300 | 5 units | 4MP20A03005 | 4MP20M03005 | 4MP20X03005 | ||

| 400 | 5 units | 4MP20A04005 | ||||

INQUIRY

INQUIRY