Cold Buried Resin

Model

- Product Feature

- Guidance

- Accessories

| Cold mounting resins Mainly intended for the metallography research sector, the LAM PLAN range of cold mounting resins offers many technical and economic advantages. The cold mounting resins are the solution for samples that do not withstand high pressure or temperature. In addition, they allow responding in a simple and efficient way to timely needs by circumventing the investment of a hot mounting press. You can achieve a large number of samples simultaneously while adjusting precisely the volume of mounting material and shape of the moulds. |

| Model | Description | Characteristics | Qty. | Ref. |

|---|---|---|---|---|

ACRYLIC RESIN 601.2 |

The fluidity of this transparent mounting resin and its very low shrinkage ensure a maximum penetration ratio in cavities It is ideal for microelectronics, optics, and microsystem applications. Compatible for conventional scanning electron microscopy (SEM) examinations. Mono-component resin is easy to dose and manipulate (no loss). Polymerization with low-temperature rise in 20 minutes in the blue light device M.M.866 + 10 minutes for the surface varnish. With no disturbing odour, it is resistant to alcohol and acids. |

Transparent Acrylic Monocomponent Maximum exothermic temperature: 95° |

Resin 1000 ml + varnish 100 ml set |

06 00601 00 |

| Resin 1000 ml | 06 01601 00 | |||

| Varnish 100 ml | 06 01602 00 | |||

EPOXY RESIN 603 |

The Resin 603 is a two-component epoxy resin without CMR substance used to achieve high-quality technical metallographic mountings at room temperature. This resin is the best choice when the transparency of the coating is a requirement. The resin has zero shrinkage, excellent adhesion to all kinds of materials, and a very good chemical resistance. With an ideally adjusted viscosity, the resin 603 is used to mount metallographic specimens with complex shapes, porosities, or delicate technical coatings. |

Transparent Epoxy 2 liquid components Maximum exothermic temperature: 105° |

Liquid 1000 ml + hardener 500 ml set |

06 00603 00 |

| Liquid 1000 ml | 06 01603 00 | |||

| Hardener 500 ml | 06 02603 00 | |||

EPOXY RESIN 603.2 |

The Resin 603.2 is a fast-curing two-component epoxy resin without CMR substance used to make technical metallographic mountings. It must be used on materials that withstand temperatures of 140°C. This transparent resin has zero shrinkage, excellent adhesion to all kinds of materials, and very good chemical resistance. |

Transparent Epoxy 2 liquid components Maximum exothermic temperature: 140° |

Liquid 1000 ml + hardener 500 ml set |

06 00603 20 |

| Liquid 1000 ml | 06 01603 20 | |||

| Hardener 500 ml | 06 02603 20 | |||

METHYL-METHACRYLATE RESIN 605 |

Versatile, it is adapted to the majority of common materials for the fast-mounting standard sample. It is possible to change the viscosity by modifying the proportion of the mixture: liquid + powder. Resistant to the principal acids used in laboratories. Solvent-free and CMR-free (no Carcinogenic, Mutagenic, toxic to Reproduction susptences). |

Green Methyl-methacrylate 2 components (powder and liquid) Maximum exothermic temperature: 108° |

Powder 1 kg + catalyst 500 ml set |

06 00605 00 |

| Catalyst 500 ml | 06 00615 00 | |||

| Powder kit (10 kg) + catalyst (5 litres) | 06 00605 10 | |||

| Catalyst (5 litres: pack. 2 x 2.5 litres)* | 06 00615 10 | |||

POLYESTER RESIN 607 |

The Resin 607 is a three-component resin based on modified polyester. This fast curing resin adheres perfectly to metal surfaces and its mechanical characteristics make it particularly effective on very hard materials. Its very low shrinkage allows edge examinations on metallographic samples. It is resistant to the main acids and bases used in laboratories. Characteristics Qty. Ref. |

Modified white polyester 3 components Maximum exothermic temperature: 122° |

Resin kit: catalyst 500 ml + hardener 250 ml + powder 750 g |

06 00607 00 |

| Catalyst 500 ml | 06 00607 10 | |||

| Hardener 250 ml | 06 00607 20 | |||

| Powder 750 g | 06 00607 30 | |||

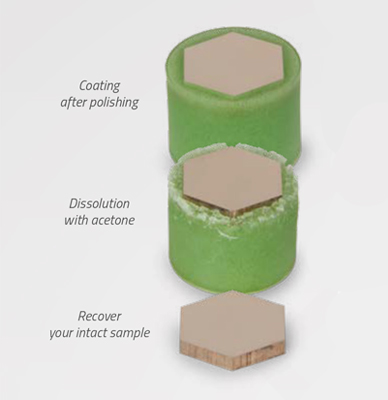

METHYL-METHACRYLATE RESIN 665 |

Cold-setting resin for sample recovery. Mounting is a step in metallographic sample preparation which enables samples to be ground and polished more ergonomically. Embedding the sample in a resin is usually irreversible and recovering the sample (if necessary) after embedding proves almost impossible. Resin 665 is a cold mounting resin that has the unique ability to dissolve in acetone. This ability is transformed into a sustainable functionality to recover metallographic specimens after mounting. After the metallographic processing of costly materials such as noble metals, it is often important from an economic and technical perspective to recover the samples from the mounting resin. |

Modified green polyester 2 components (Powder + Liquid) Maximum exothermic temperature: 112° |

Powder 1 kg + catalyst 500 ml set |

06 00665 00 |

| Catalyst 500 ml | 06 02665 00 | |||

| Powder 1 kg | 06 01665 00 |

| Model | Description | Characteristics | Qty. | Ref. | |

|---|---|---|---|---|---|

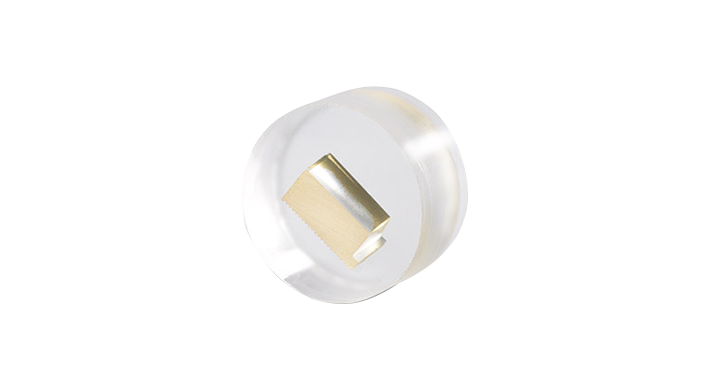

METHYL-METHACRYLATE RESIN 609 |

A perfectly transparent resin used for precision parts, notably those of the electrical or electronics industry. It renders the sample perfectly visible, which allows the analysis of precise points. It must be used with the pneumatic device M.M.808 to obtain optimum transparency. The methyl-methacrylate resin 609 is available in the Plastichrome version – 5 transparent colors to simplify the classification of samples. Solvent-free and CMR-free (no Carcinogenic, Mutagenic, toxic to Reproduction susptences). |

||||

| Methyl-methacrylate Transparent 2 components (powder + liquid) Maximum exothermic temperature: 99° |

Powder 1 kg + catalyst 500 ml set | 06 00609 00 | |||

| Catalyst 500 ml | 06 00619 00 | ||||

| Powder 1 kg | 06 00609 20 | ||||

| Powder 10 kg + catalyst 5000 ml set | 06 00609 10 | ||||

| Catalyst 5000 ml (pack. 2 x 2500 ml)* | 06 00619 10 | ||||

METHYL-METHACRYLATE RESIN 609 PLASTICHROME |

Characteristics | Qty. | Color | Ref. | |

| Methyl-methacrylate Transparent coloured 2 components (powder + liquid) Maximum exothermic temperature: 99° |

Powder 1 kg + Catalyst 500 ml set |

BLUE | 06 0071B 00 | ||

| YELLOW | 06 0071J 00 | ||||

| ORANGE | 06 0071O 00 | ||||

| RED | 06 0071R 00 | ||||

| GREEN | 06 0071V 00 | ||||

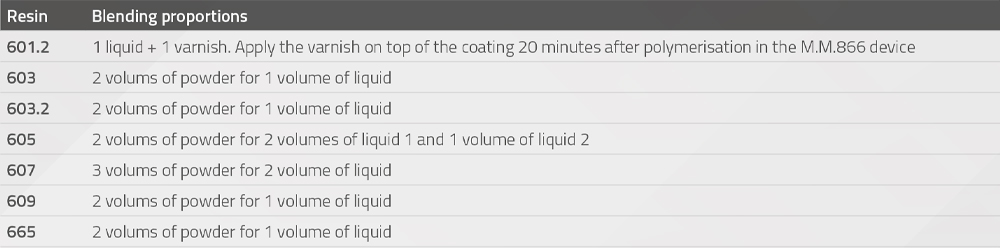

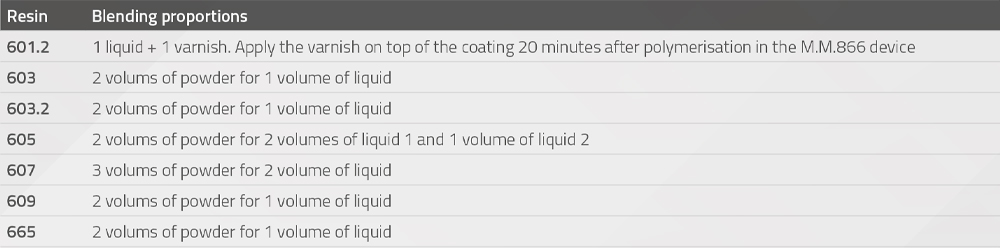

Advice on the use of LAM PLAN cold resins

Procedure for cold mounting

Keep the thin samples on the slice. Mix the resin components in the indicated proportions. Mix gently to avoid creating air bubbles. Pour the resin into the mould to the desired level and allow it to cure in the open air or in an M.M.808 pressure vessel to remove any bubbles or pores. To limit heating and shrinkage, fill the mould in successive layers.

Keep the thin samples on the slice. Mix the resin components in the indicated proportions. Mix gently to avoid creating air bubbles. Pour the resin into the mould to the desired level and allow it to cure in the open air or in an M.M.808 pressure vessel to remove any bubbles or pores. To limit heating and shrinkage, fill the mould in successive layers.

| Model | Description | Type | Qty. | Dim. (mm) | Ref. |

|---|---|---|---|---|---|

Moulds with removal bottom |

Mainly used with the transparent mounting resins (601.2, 609, 603 & 603.2). | 681 | 5 | 25 | 06 00681 10 |

| 5 | 30 | 06 00681 20 | |||

| 5 | 32 | 06 00681 30 | |||

| 5 | 40 | 06 00681 40 | |||

Flexible rectangular cold mounting moulds |

Specifically, for cold mounting resin, adapted to complex and nonstandard shapes, many dimensions available, made of a flexible material to facilitate mould removal (Not recommended for EPOXY resins). | Flexible 670 | 5 | 70 x 30 x 40 | 06 00670 10 |

| 5 | 100 x 42 x 30 | 06 00670 20 | |||

| 5 | 120 x 50 x 30 | 06 00670 30 | |||

| 5 | 100 x 70 x 30 | 06 00670 40 | |||

| Flexible 670 4 pieces set |

1 | 70 x 30 x 40 | 06 00670 00 | ||

| 1 | 100 x 42 x 30 | ||||

| 1 | 120 x 50 x 30 | ||||

| 1 | 100 x 70 x 30 | ||||

Flexible cylindrical cold mounting moulds |

Available in all standard diameters for central and individual pressure sample holders, made of a flexible material to facilitate mould removal. (For an intensive use of the EPOXY 603 resin, it is preferable to use moulds with removable bottoms). |

Flexible 625 | 5 | Ø 25 | 06 00625 00 |

| Flexible 630 | 5 | Ø 30 | 06 00630 00 | ||

| Flexible 632 | 5 | Ø 32 | 06 00632 00 | ||

| Flexible 640 | 5 | Ø 40 | 06 00640 00 | ||

| Flexible 650 | 5 | Ø 50 | 06 00650 00 | ||

| Flexible 660 | 5 | Ø 60 | 06 00660 00 |

Cups and spatulas

Paper cups and wooden spatulas to mix cold mounting resins.

| Characteristics | Qty. | Capacity | Ref. |

|---|---|---|---|

| Paper cups | 200 | 200 ml | 06 00696 00 |

| Set: cups and spatulas | 400 cups 400 spatulas |

06 00698 00 |

Unmoulding agent

Recommended for PHENOFREE, 633 and 634 resins.

| Characteristics | Qty. | Ref. |

|---|---|---|

| SOLILUB | ||

| Anti-stick powder for hot mounting process |

50 g pot | 06 00683 00 |

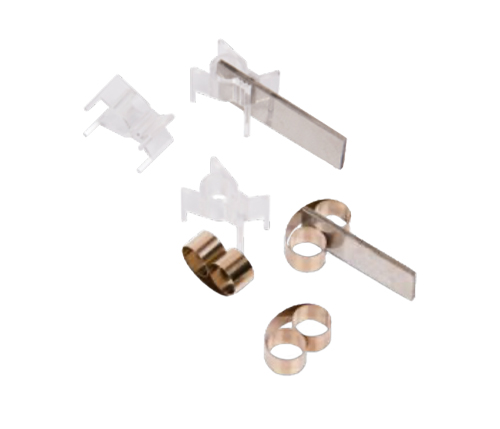

Blade-holders

For the vertical positioning of thin sections, use of could mounting resin.

| Characteristics | Qty. | Thickness in mm | Ref. |

|---|---|---|---|

| Blade-holder series 690 | 100 | 1 | 06 00690 10 |

| Blade-holder series 691 | 100 | 2 | 06 00690 20 |

| Blade-holder series 692 | 100 | 3 | 06 00690 30 |

Holding clips

| Characteristics | Qty. | Ref. |

|---|---|---|

| CLIPS TYPE 3 | ||

| Holding plastic, raised clips to use with cold mounting resin. |

100 | 06 00694 00 |

| CLIPS TYPE 5 | ||

| Holding clips type 5 metal clips to use with hot mounting resin. |

100 | 06 00693 00 |

INQUIRY

INQUIRY