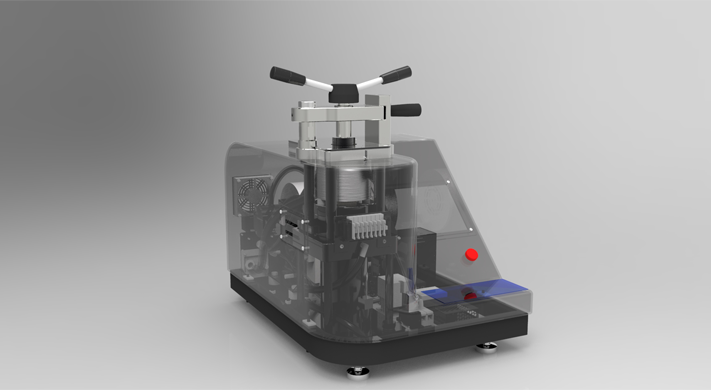

TNM-AX Metallographic Pretreatment

Model

TNM-32AX

- Product Feature

- Product Specification

Desktop Metallographic Precision Cutting Machine

This cutting machine can apply to small and fragile products. It contains X direction fix size function, it’s suitable for a sample that needs displacement accuracy, is easy to use, and can control the cutting speed and maintain a certain speed. Focus on the certain field such as metal hardness stable heat treatment process, determining surface coating size, ceramic material electrical parts observation and related skill development quality management, etc.

One Touch Automatically Sampling

Only need to press one button then you can open the machine, we remove manual and sub-automatic ideas, to avoid manual factors resulting in sampling problems, and increase to the highest standard in Taiwan.

Reduce the Cost and Increase the Efficiency

TNM-AX series mounting press, including the pre-heating function, it can turn on when continuously making a big amount of sampling. You can pre-heat the mold, it can safely power and increase production.

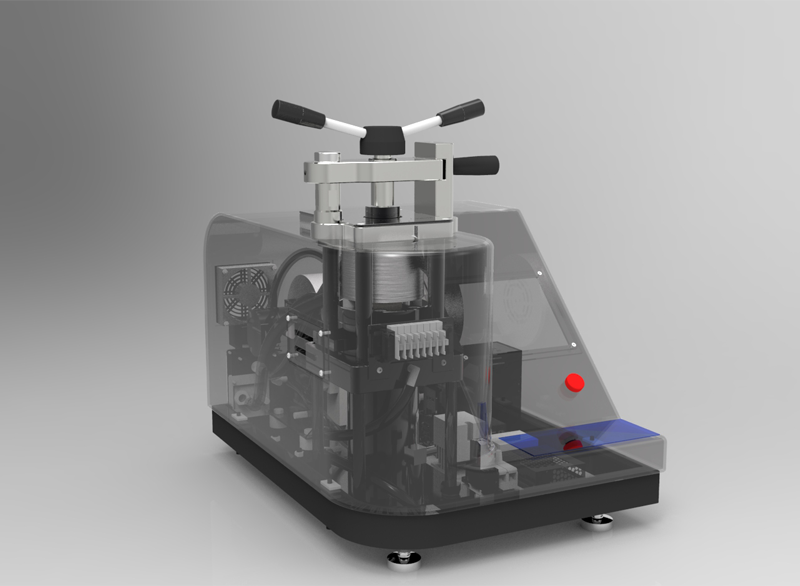

Patented Effortless Packing Machine

Not like before need to put so much effort to aim the filler to the mold, the brand new TNM series have a spin down design, you only need to put the product and resin to the mold and take the holder close to the positioning device, the mold will automatically aim itself, only need to swing the handle to lock the device, then you can finish the filling job easily. It can also avoid mold breaking.

TNM-AX series provide acrylic-making mode, the transparent acrylic mounting sampling, can see the structure in the side of the product, or for demonstration uses.

This cutting machine can apply to small and fragile products. It contains X direction fix size function, it’s suitable for a sample that needs displacement accuracy, is easy to use, and can control the cutting speed and maintain a certain speed. Focus on the certain field such as metal hardness stable heat treatment process, determining surface coating size, ceramic material electrical parts observation and related skill development quality management, etc.

One Touch Automatically Sampling

Only need to press one button then you can open the machine, we remove manual and sub-automatic ideas, to avoid manual factors resulting in sampling problems, and increase to the highest standard in Taiwan.

Reduce the Cost and Increase the Efficiency

TNM-AX series mounting press, including the pre-heating function, it can turn on when continuously making a big amount of sampling. You can pre-heat the mold, it can safely power and increase production.

Patented Effortless Packing Machine

Not like before need to put so much effort to aim the filler to the mold, the brand new TNM series have a spin down design, you only need to put the product and resin to the mold and take the holder close to the positioning device, the mold will automatically aim itself, only need to swing the handle to lock the device, then you can finish the filling job easily. It can also avoid mold breaking.

TNM-AX series provide acrylic-making mode, the transparent acrylic mounting sampling, can see the structure in the side of the product, or for demonstration uses.

|

|

|

|

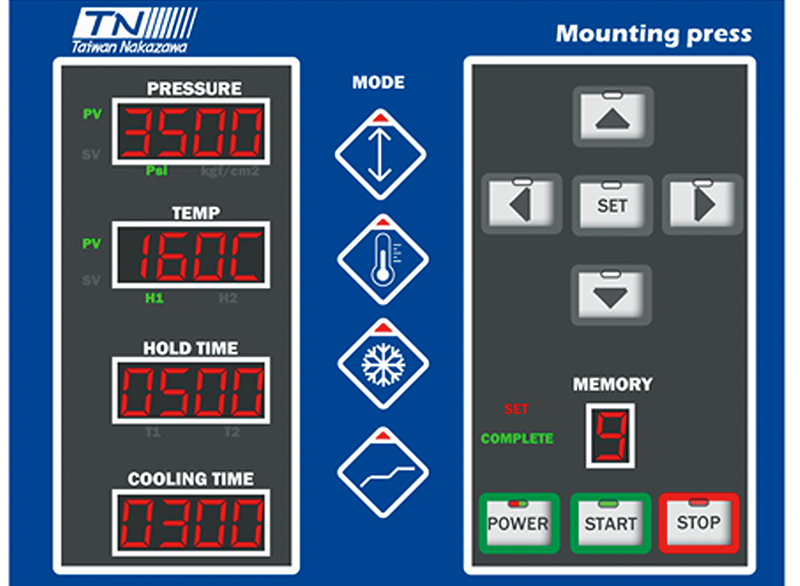

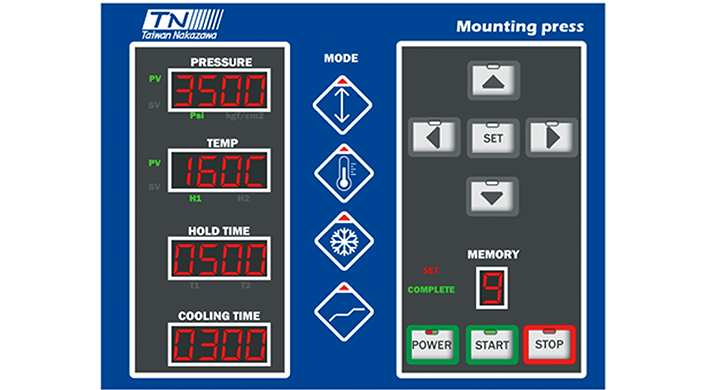

Programmable Module It contains 4 major production modes and 9 memory modules, according to the different features of the various metal material, and resins the memory function of the molding pressure, temperature, cooling time, and other factors, and is fit with various consumables on the market. Mode 1: Widely used for most of the hot soild poly. Mode 2: Hot plastic, such as poly. Mode 3: Need to do separately temperature and pressure control. Mode 4: Have to match the pressure compensation with the target temperature resin. |

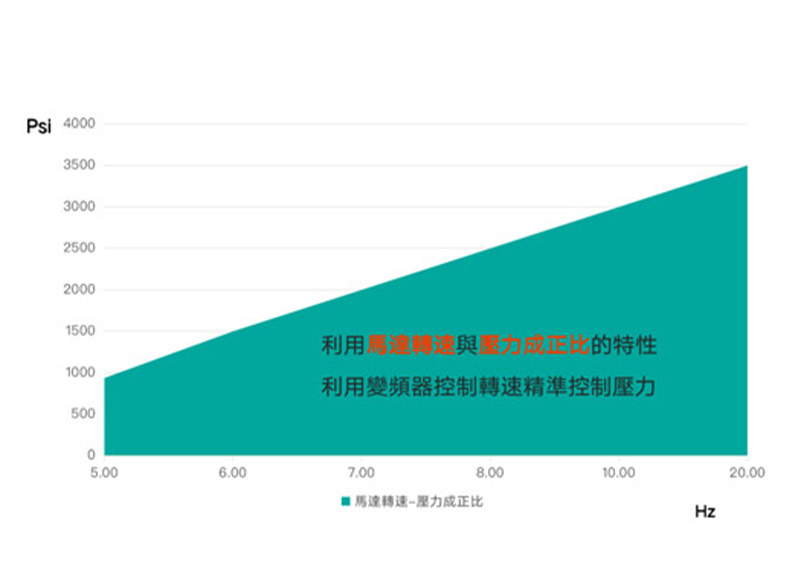

| Volume Control Compare to the old equipment use the electromagnetic motors as a mounting driving method, the new TNM series has make a new design on hydraulic drive. We use a frequency control system, It can not only lower down the volume, and also the accuracy of the pressure has also reached a new high level. |

|

|

Safety System All machines are certificated by CE, and in every sampling process used, we put the safety of the user as our first priority. All the structure and experiment data are all internationally recognized. |

| Lesser Faster Better In sampling, every second is important, any extra time will affect the sampling result. The TNM series use a temperature control and cooling system, letting the sampling efficiency to the maximum. The special chamfer mold can reduce the mounting working load. |

|

|

Cooling Circulation Water tank You can choose the cooling circulation water tank system to use with your TNM series, the cold water after mounting will go to the heat dissipation water tank, passing the strong suction by the fan, letting air flow through the radiator from front to back to dissipate the heat. This is suit for the environment that couldn't install the waterway system. |

| Item | Product specifications | ||

|---|---|---|---|

| TNM-32AX | TNM-40AX | ||

| Type | Desktop | ||

| Shell | Fiberglass Reinforced Plastics (FRP) | ||

| Parameter | Size | ψ32mm | ψ40mm |

| Maximum Pressure | Max. 4000PSI (280kgf/cm2) | Max. 3200PSI (224kgf/cm2) | |

| Pressure control | Variable-frequency Control | ||

| Quantity | 1-2 Piece | ||

| Total power | PID Temperature Control,110-200°C Variable | ||

| Operation panel | Mode | 1. Automatic pressure compensation ( Phenolic Resin ) | |

| 2. Pressurize during cooling phase ( Acrylic Resin ) | |||

| 3. Segmented temperature and pressure compensation ( Phenolic Resin Optimization ) | |||

| 4. Pressure compensation when reaching the target temperature ( Acrylic Resin Optimization) | |||

| Function | Preheating temperature , heating time , molding temperature , cooling time molding , pressure setting , power unit switching Kgt/PSI | ||

| Temperature unit switch, temperature compensation, buzzer mode switch, sample quantity record, production module memory | |||

| Module memory Function | 1.Making pattern 2. Pressure 3. Temperature 4. Holding time 5. Cooling time | ||

| ONE TOUCH | 1. Put sample and embedded power in the tube , and choose the making pattern according to the demand. | ||

| Automatic | 2. Turn the upper cover to the position and lock it | ||

| 3. Push the START button then auto run the cycle | |||

| 4. Automatic heating, pressure compensation, cooling then complete with beep | |||

| Pre-heating function can be turned on, which can signficantly improve sample preparation efficiency | |||

| Safty | Safe temperature | When out of the safe temperature ,it's not allowed to take samples, and the system will continue to automatically cooling down | |

| Emergency switch | Emergency button is pressed, all functions stop and display "EMG" | ||

| Overload protection | The machine has a complete overload protection mechanism | ||

| Cooling system | The cooling fan performs heat dissipation according to the panel instructions | ||

| Supply | Electricity | single phase 220V 60/50Hz | |

| Heating power | Power:1800W | ||

| Total power | 2400W | ||

| Dimension | W450*D695.5*H569mm | ||

| Weight | 82kg | 83kg | |

| Cooling water | Runing water ( Option:circulating cooling water tank ) | ||

| water inlet diameter 3/8 inch | |||

| water outlet diameter 5/8 inch | |||

| Circulating cooling water ( optional ) | electricity | single phase 220V 60/50Hz | |

| Dimension | W566*D425*H477mm | ||

| Capacity | 40L | ||

| Weight | 30kg | ||

| coolant | pure water add coolant | ||

| Standard accessories | Molding resin*1 can(500g)、spoon*1、funnel*1、inlet and outlet pipes 2M*2、release agent*1can | ||

INQUIRY

INQUIRY