TNC-ASL Metallographic Pretreatment

Model

TNC-255ASL, TNC-305ASL, TNC-355ASL, TNC-355ASL-FA

- Product Feature

- Product Specification

Made in Taiwan All Series are Patented

100% design by the Taiwan team cooperates with the top supplier in the industrial industry and collaborate with the expert in metal manufacture and the metallographic field, to create a precision abrasive cutting machine that is suitable for the metal manufacturing and technology industry can be widely used in scientific research institutions, car industry, aerospace industry, metal manufacturing heat treatment, etc.

Focus on related fields: qualitative hardness, heat treatment technology research and judgment, carburizing and hardening layer thickness, induction hardening, welding area hardness, hard bonding, electrical parts observation-related technology development and quality management, and other pre-processing processes.

100% design by the Taiwan team cooperates with the top supplier in the industrial industry and collaborate with the expert in metal manufacture and the metallographic field, to create a precision abrasive cutting machine that is suitable for the metal manufacturing and technology industry can be widely used in scientific research institutions, car industry, aerospace industry, metal manufacturing heat treatment, etc.

Focus on related fields: qualitative hardness, heat treatment technology research and judgment, carburizing and hardening layer thickness, induction hardening, welding area hardness, hard bonding, electrical parts observation-related technology development and quality management, and other pre-processing processes.

|

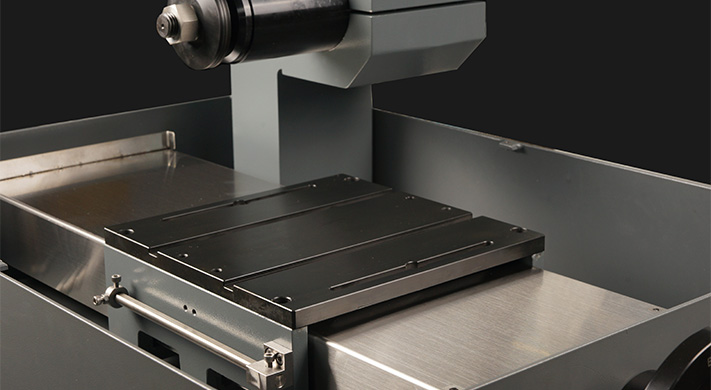

Bright and Humanize Working Environment Cutting room is the main working area for the user. The new TNP series is based on the user's height and operation habits to redesign the size of the working area and the brightness. A bright and spacious working environment can increase working efficiency and comfort so that cutting is not a boring and messy job anymore. |

| Large fast Stepless Slides Fixture(TNC-355ASL) The brand new positioning fixture combines high flexibility and strong clamping power for complex products and increases the safety function. The stepless slide design can fit in different sizes of products so that you don't need to reinstall it again. The maximum opening is 210mm. |

|

|

Intelligence Feeding Function (optional) Depends on the different cutting features of the material, use the correspondence of current value and cutting load to process personify cutting back and forth. By using this function can cut bigger and stronger material, and extend the service life of the cutting disk, lower the cost. |

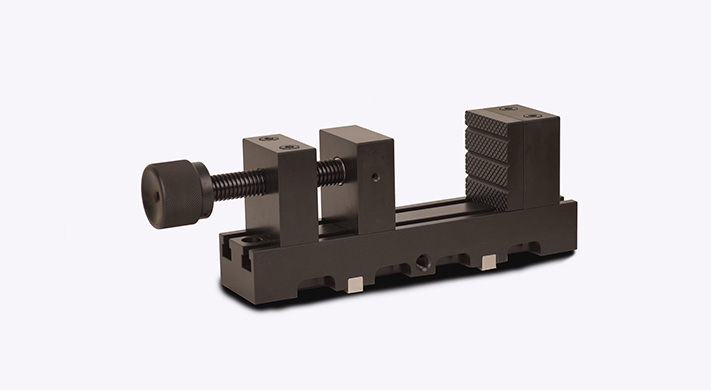

| Small and Powerful Screw Increaser fixture It's a screw increaser suitable for small products. The machine is made of the whole metal. Tough and useful, after the heat treatment, not only the machine's function ability and also protect it become deterioration. |

|

Easy to maintain

For the TNC series cutting machine, we pack the cutting system in the stainless protection device will reduce the need for maintenance. Only need to add the oil to the screw. You can also call TN service line to purchase the regular maintenance service, our specialist will assist you.

Magnetic Filter Device(optional)

It can reduce the quantity of cleaning the water box, and reduce the left over to make the liquid become deterioration. It can extend the machine using time and cost down the value. Also, it will reduce the choking problem of the cooling system.

All Machine are Certificated by CE

Safety is our first concern, whether is electrical safety or doing the daily cutting job. We follow an international safety CE system, to make sure our users are safe.

| ITEM | Model/Specification Description | |||

|---|---|---|---|---|

| TNC-255ASL | TNC-305ASL | TNC-355ASL /TNC-355ASL-FA | ||

| Type | Standing | |||

| Transmission system | form | High efficiency induction motor belt drive mechanism | ||

| Cutting Motor | 3 HP (60/50Hz) | 5 HP (60/50Hz) | 7.5 HP / 10HP (equipped with frequency converter) | |

| Rotational Speed | 2670 (60Hz) | 2250 (60Hz) | 1980 (60Hz) | |

| (RPM) | 2640 (50Hz) | 2230 (50Hz) | 1980 (50Hz) | |

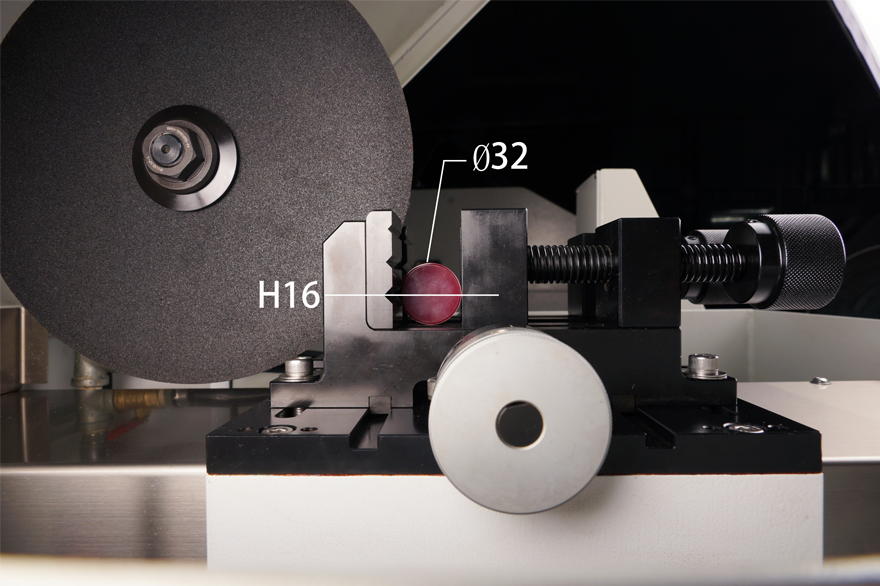

| Cutting sheet specifications | Outside diameter of cutting disc | Ø255mm | Ø305mm | Ø355mm |

| Inside diameter of cutting disc | Ø31.75mm | Ø31.75mm | Ø31.75mm | |

| Sample clamping | Fixture type | Thread locking fixture | ||

| Opening distance adjustment | Slider to adjust the distance between movable jaws | |||

| Locking method | Thread locking, tool adding force | |||

| Fixture opening | Maximum 123mm | Up to 210mm | ||

| Opening (mm) | Maximum 50mm (handwheel adjustment) | Maximum 40mm (handwheel adjustment) | ||

| X Movement (mm) | 82m | 84mm | 101mm | |

| Cutting Height (mm) | 500mm | |||

| Control System | Panel form | Waterproof IP55 Physical Hard Button Panel | ||

| Features | LED digital display board: 1. Feed speed mm/min 2. Load current ampere value A 3. Life record 4. Intelligent feed reciprocating times | |||

| Automatic feed speed adjustment | ||||

| Manual automatic function start and stop | ||||

| Intelligent feed function setting (optional) | ||||

| Cooling system function start and stop | ||||

| Complete the three modes of buzzer reminder: 1. Turn off 2. Unlimited buzzer reminder 3.30 seconds buzzer reminder | ||||

| Magnetic filter system function start and stop (optional) | ||||

| Feeding device | Tool setting method | Visual or (optional laser tool setting device) | ||

| Manual advance and retreat | Use advance hand to lose | |||

| Feeding Speed | Freely set the feed speed and cutting end point, automatic feed | |||

| Auto retract | After the worktable reaches the cutting end point, it automatically returns to the cutting origin at full speed, and then the buzzer prompts | |||

| Smart feed | Optional (Smart current reciprocating cutting, please refer to the description of smart feed) | |||

| Manual/automatic switch | Patented manual automatic integrated knife feed and manual input (switching time is about 1 second) | |||

| Stroke | 300mm | |||

| Lighting device | Type | IP67 high brightness LED lamps | ||

| Safety function | System self-protection function | In addition to passive overload protection, self-protection function (load upper limit) can be set | ||

| Current overload | The feed function stops and the worktable returns to the cutting origin | |||

| Emergency button | In an emergency, press the emergency stop button to stop all functions | |||

| Observation window | Safety tempered glass | |||

| Door safety device | Lift up the slide rail, air pressure support and anti-pinch | |||

| After closing the hatch correctly, the spindle function cannot be started | ||||

| Spindle action stops when opening hatch during operation | ||||

| Overload protection | Set the overload current and motor overload protection device | |||

| Cooling device | Volume | 80L | 80L/* 200L | |

| Circulating Pump | 1/8 HP | 1/4 HP | ||

| Circulating water | 48L / min | 85L / min | ||

| Cooling water hose | 4 groups | |||

| Cleaning hose | 1 | |||

| Filter method | Filter and sedimentation tank | |||

| Magnetic filter | Optional | |||

| weight | 32kg | 35.4kg | ||

| Size (mm) | D600*W500*H270 | |||

| Electricity | AC 220V /380V 50HZ/60Hz 3P, Power cord length 3500mm | |||

| Power | 2500w | 4000w | 6000w / 8000w | |

| Machine | APPEARANCE | D980*W900*H1500mm | D1020*W900*H1600mm | |

| Weight | 439.5kg (220V) | 445kg (221V) | 541kg (222V) | |

| 446.5kg (380V) | 452kg (380V) | 548kg (380V) | ||

| Standard Accessories | Cutting Disc*2pcs、Coolant oil (2L)*2btl、Toolbox*1set | |||

INQUIRY

INQUIRY