TNP-FRX Manual

Model

TNP-1020FRX,TNP-2020FRX

- Product Feature

- Product Specification

|

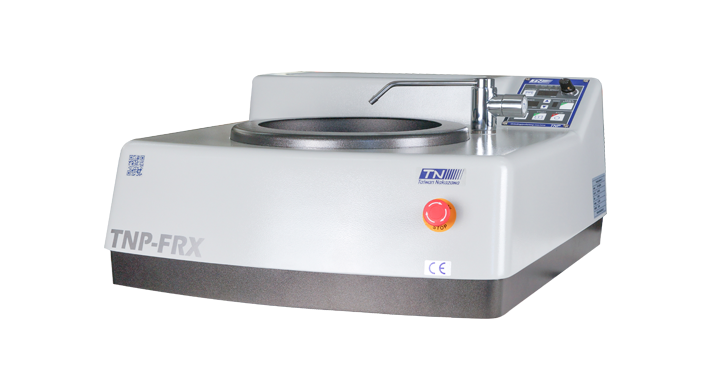

Strong and Durable Special Structure We put the high-efficiency transmission unit on the aluminum base, it highly increases the comfortableness and can absorb the vibration when doing grinding. Compared with the products on the market with cast iron bases, flatness can be obtained during grinding and reduced noise. |

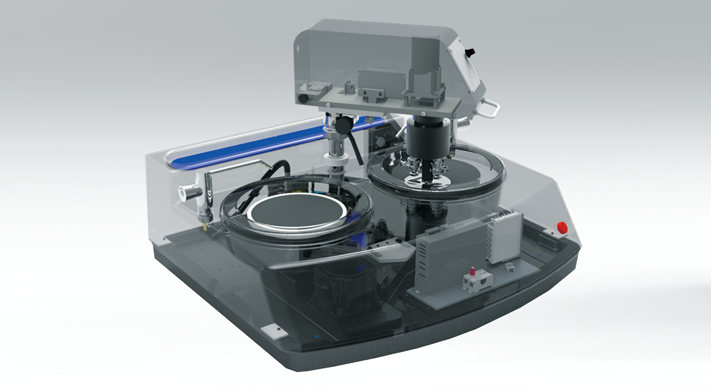

| Support Fast Disc Change System It is suited for any type of cameo disk system, the one-piece aluminum disk surface, it can stick the fast magnetic adapter plate, easy to cut all types of grinding material, Significantly increasing the application range of equipment. |

|

|

Easy to Clean and Maintain Cleaning the grinding and polishing equipment has increased a lot of workloads, the new anti-fouling FRP case, not only looks beautiful, and also can save a lot of effort when doing daily cleaning and maintenance. |

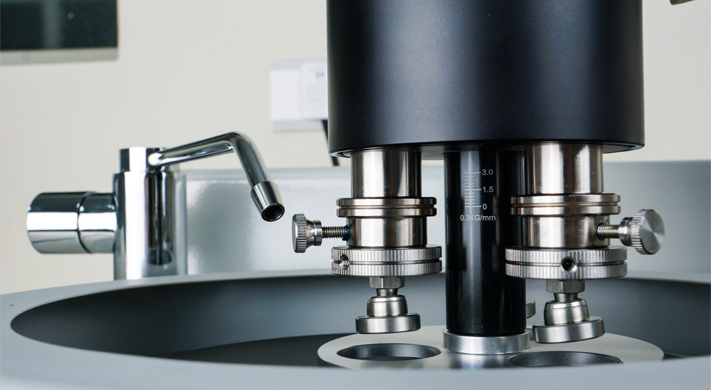

| Cooling Device We invite the top bathroom equipment designer in Taiwan, to redesign the stainless steel ceramic spray hose that is for the special need of metallographic grinding and polishing. Including the amount of spray water and angle, it looks beautiful and useful. |

|

|

Custom Grinding / Polishing Parameters The waterproof membrane panel has 9 groups of grinding and polishing parameter memory functions which can be made at any time for different material needs, and apply to different requirements of grinding and polishing. Including grinding indenter and disk surface spin speed, working time, and parameter memory setting function. |

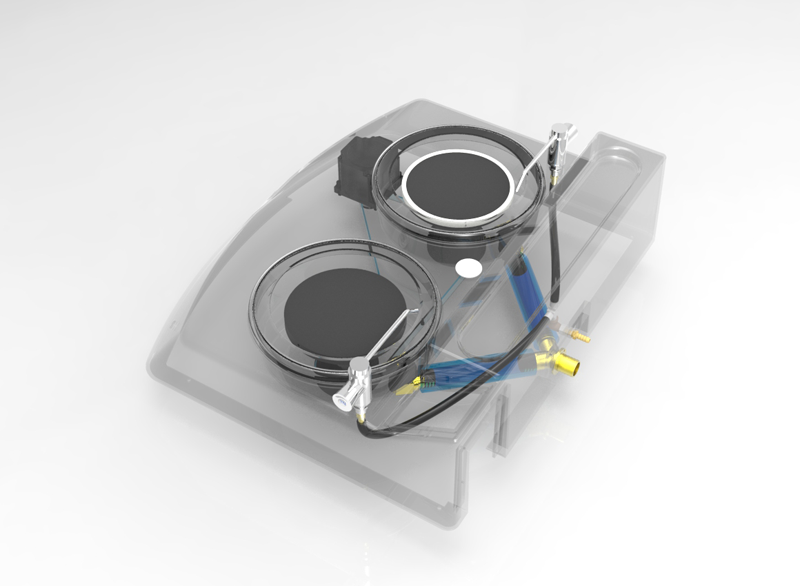

| Anti-chocking Triangle Waterway design The past grinding/polishing machine all had the problem that the consumables chocking the waterway, to solve this, we have designed the anti-chocking waterway. We make use of the shortest distance and angle of the waterway and change the material of the tube, these can reduce the chocking problem. |

|

|

Automatic Grinding / Polishing Unit The redesigned grinding/polishing units are deeply loved by the Taiwan customer and focus on rigidity and convenience, making the simple and suitable for Grinding & Polishing Machines. It’s easy to use and setting. It is good for the Material that needs to do grinding and polishing for a long time. |

| Automatically Dripping Device (optional) Manual and automatic polishing/grinding machines, grinding/polishing consumables for automatic dripping devices, diamond suspension, alumina powder, and final polishing liquid are all available to use. |

|

| Item | Model/Specification Description | |||

|---|---|---|---|---|

| TNP-1020FRX | TNP-1025FRX | TNP-2020FRX | TNP-2025FRX | |

| Type | Desktop (high-strength aluminum alloy base and surface hardened FRP chassis) | |||

| Operation panel | Waterproof membrane type button panel | |||

| Grinding the surface | 1 | 2 | ||

| Grinding disc size | 200mm | 250mm | 200mm | 250mm |

| Features | 1. The grinding schedule can be preset, and the grinding method can be standardized 2. It has 9 sets of memory scheduling parameters | |||

| parameter settings | Steering, speed, time | |||

| Warning system | Have | |||

| Grinding method | Manual | |||

| Grinding speed | MAX800rpm 60HZ/50HZ | |||

| Grinding disk motor specifications | AC 220V 400W brushless motor | |||

| Water supply device | Ceramic needle valve integrated forged faucet | |||

| Drainage system | Natural drainage straight-through type does not block | |||

| Inlet pipe aperture | 1/4 inch | |||

| Outlet pipe aperture | 1 inch | |||

| Total power of machine | 500W | |||

| Power supply | AC220V single phase | |||

| Machine size | W556*D652*H303mm | W796*D726*H303mm | ||

| Weight | 36kg | 37kg | 57kg | 58kg |

| Standard accessories | Water sandpaper P600, P800, P1200*2 each, polishing flannel*2, 0.3um alumina powder*1 can (100g), drip bottle*1 | |||

INQUIRY

INQUIRY