TNP Automatic Metallographic Grinding & Polishing Machine

- Product Feature

- Product Specification

Metallographic samples and tools can be placed to keep the desktop fresh and avoid laboratory clutter

The well-built cast aluminum base is equipped with an efficient transmission unit, which greatly increases the comfort of use and can effectively absorb the vibration generated during grinding. Compared with the products on the market with cast iron brackets as the base, you can get better results during grinding. Flatness, and reduces the noise in the laboratory.

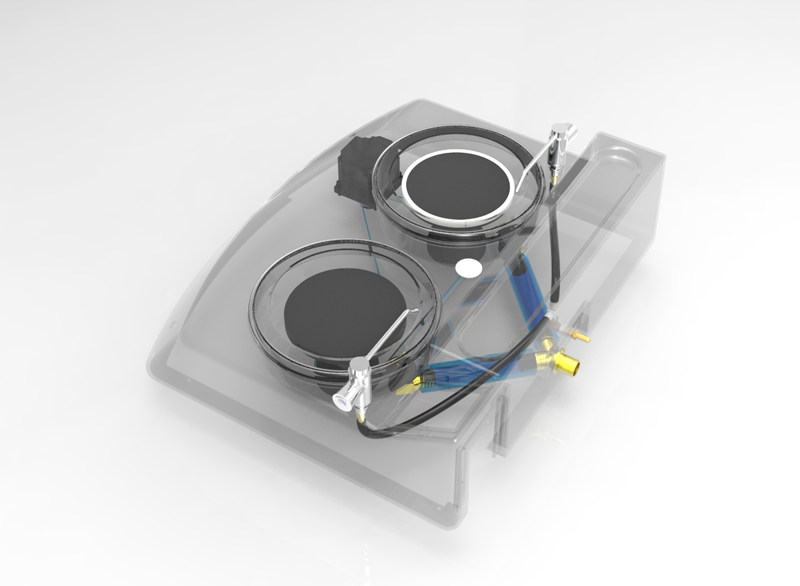

Compatible with all kinds of diamond grinding disc systems, one-piece cast aluminum disc surface, can stick fast magnetic The adapter plate is convenient for quickly switching various grinding consumables, which greatly increases the application range of the equipment.

The cleaning of grinding and polishing equipment often increases a lot of work in daily work. The new anti-fouling FRP shell is not only beautiful in appearance but also convenient and labor-saving.

Stainless steel ceramic spray hose invites top manufacturers of sanitary equipment in Taiwan and combines different industries to focus on users The new design is suitable for the special needs of metallographic grinding and polishing, including the amount of spray water, the angle, and the beauty and Practicality

The waterproof membrane panel has 9 groups of grinding and polishing parameter memory functions, which can be called at any time according to different materials and requirements, and can be applied to different grinding and polishing needs. Including the setting memory function of parameters such as grinding head and disk surface speed, working time, and so on.

In the past, grinding and polishing machines had the problem that the waterway was blocked by the grinding consumables, in order to solve the problem For a long time the user’s troubles, we have designed a waterway to prevent clogging and use the shortest waterway distance And the angle and changing the pipe material can reduce the chance of blockage.

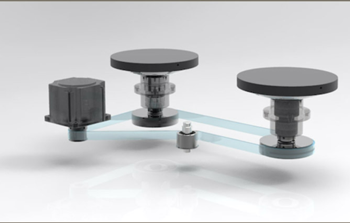

Redesigned the grinding unit group which is loved by Taiwan users. Aiming at rigidity and ease of use, a simple mechanism conforming to the principle of metallographic grinding and polishing is created. It is easy to use, easy to operate and set. It is suitable for materials that need to be ground and polished for a long time.

Accurately fits the TNP grinder drain spiral inner groove design Smooth surface is not easy to be stained with dirt Easily removable Clean it thoroughly The replaceable feature can make the machine still look new

| project | Model/Specification Description | |||

|---|---|---|---|---|

| TNP-1020FRX-A3/A5 | TNP-1025FRX-A3/A5 | TNP-2020FRX-A3/A5 | TNP-2025FRX-A3/A5 | |

| Appearance structure | Desktop (high-strength aluminum alloy base and surface hardened FRP chassis) | |||

| Operation panel | Waterproof membrane type button panel | |||

| Grinding the surface | 1 | 2 | ||

| Grinding disc size | 200mm | 250mm | 200mm | 250mm |

| Features | 1. The grinding schedule can be preset, and the grinding method can be standardized 2. It has 9 sets of memory scheduling parameters | |||

| parameter settings | Steering, speed, time (both polishing disc and automatic head are equipped) | |||

| Warning system | Have | |||

| Grinding method | Manual / Auto | |||

| Grinding speed | MAX800rpm 60HZ/50Hz (adjustable forward and reverse rotation) | |||

| Grinding disk motor specifications | AC 220V 400W brushless motor | |||

| Auto head motor specifications | DC 24V 80W | |||

| Automatic head speed | MAX 150rpm (adjustable forward and reverse rotation) | |||

| Number of Grinding Test Pieces | 3/5 | 3/5 | 3/5 | 3/5 |

| Specimen size | Ø32mm (25, 30, 40mm can be selected) | |||

| Water supply device | Ceramic needle valve integrated forged faucet | |||

| Drainage system | Natural drainage straight-through type does not block | |||

| Water inlet aperture | 1/4 inch | |||

| Drainage aperture | 1 inch | |||

| Total power of machine | 600W | |||

| power supply | AC220V single phase | |||

| Machine size | W556*D652*H568mm | W796*D727*H568mm | ||

| weight | 52kg | 53kg | 73kg | 74kg |

| Standard accessories | Water sandpaper P600, P800, P1200*2 each, polishing flannel*2, 0.3um alumina powder*1 can (100g), drip bottle*1 | |||

INQUIRY

INQUIRY